In the global sports equipment market, more and more entrepreneurs, distributors, and sports brands desire to start their own basketball brands. However, establishing their own manufacturing system, product design, and quality control is not a simple task. For brand owners who hope to have high-quality basketball products loaded onto the market in a short time, choosing a professional OEM manufacturing (Original Equipment Manufacturing) partner is a good way to achieve brand success.

This article will take you step by step through how to create your own basketball brand through OEM manufacturing, from creating your design and logos through mass production, completely revealing the process of making a successful basketball brand.

What is OEM Manufacturing? Why is it suitable for building a basketball brand?

OEM Manufacturing (Original Equipment Manufacturing) refers to a partnership model in which the brand provides the design or concept, while the manufacturer handles production.

For brand owners looking to enter the basketball market, OEM offers the following advantages:

- No need to build their own factory: Reduced production costs;

- Quick market response: Short design to mass production cycle;

- Stable product quality: Manufacturing and testing are performed by experienced factories;

- Focus on brand marketing: Brand owners can focus on promotion and sales.

Compared to ODM (Original Design Manufacturing), OEM allows brands to maintain greater brand control while ensuring product quality and consistency.

Five Key Steps to Building a Basketball Brand

1. Clarify Market Positioning and Product Direction

Before beginning an OEM partnership, you must first determine your target market:

- Is it for professional competition, youth training, or leisure and entertainment?

- Are you aiming to create a high-end series or a mass-market sports model?

Different positioning will determine the material, specifications, and design style of the basketball. For example, game balls prioritize feel and airtightness, while training balls emphasize durability and value.

2. Custom Design and Logo Creation

Brand vision is the soul of a basketball brand. OEM manufacturers typically offer a variety of design options, including:

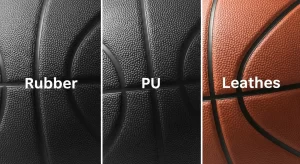

- Surface material and texture options (PU, synthetic leather, genuine leather, etc.)

- Color and color scheme

- Logo printing method (silk screen printing, heat press, hot stamping, embossing)

Recommendation:

The logo design should be simple and clear to ensure easy recognition when embossed or silk-screened on the ball.

At Normansport, customers can directly provide logo files in AI or PDF format, and we will quickly prepare proofs for you.

3. Material and Manufacturing Process Selection

The key to a high-quality basketball lies in its materials and craftsmanship.

- Exterior Material: PU leather offers excellent feel and wear resistance, making it suitable for professional training and competitions; rubber basketballs are suitable for outdoor use and are more affordable.

- Inner Bladder: The highly airtight butyl bladder ensures stable air pressure over time.

- Stitching: Precision stitching ensures consistent roundness of the ball, enhancing rebound and control.

In OEM manufacturing partnerships, professional manufacturers will provide the optimal material combination and technical solutions based on the customer’s budget and usage scenario.

4. Sample Development and Confirmation Process

The sample stage is crucial before entering mass production.

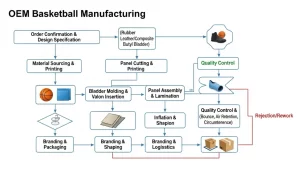

The typical process includes:

- Customer provides design and logo files;

- Factory produces samples (7–15 days);

- Customer confirms sample feel, color, and logo quality;

- Final production begins after sample confirmation.

During the sample stage, details such as material thickness, color contrast, and logo placement can be freely adjusted to ensure the final product aligns with the brand’s positioning.

5. Mass Production and Quality Inspection

Established OEM basketball manufacturers have comprehensive quality control processes:

- Raw material testing and incoming inventory management

- Compression molding and bonding processes

- Airtightness, rebound, and wear resistance testing

- Appearance and dimensional consistency inspection

At Normansport, every basketball leaving our factory undergoes rigorous testing to ensure compliance with international standards and brand requirements. We also provide customized packaging and international shipping support upon request.

How to choose the right OEM basketball manufacturer?

Choosing a manufacturing partner is crucial to brand success. The following evaluation criteria are used:

- Years of experience in basketball manufacturing.

- Flexible customization of logos, packaging, and colors;

- A rigorous quality inspection system;

- International export experience and familiarity with overseas buyers’ needs.

A good OEM manufacturer is more than just a producer; it is also a behind-the-scenes supporter of the brand.

OEM Partnership: The True Path from Creativity to Brand Success

The success of many independent sports brands is inseparable from professional OEM partnerships.

Starting with a creative logo, through the factory’s professional design, process refinement, and mass production capabilities, brand owners can quickly develop a complete product line and quickly enter the market.

OEM partnerships allow brands to focus more on promotion and sales, while outsourcing production to reliable partners. This is the mainstream model in the modern sporting goods industry.

Conclusion: Make Manufacturing the Starting Point of Your Brand Dream

Building a successful basketball brand requires not only passion and creativity, but also strong production support.

Through OEM manufacturing, brand owners can achieve product launch at a lower cost and faster speed, turning their dreams into reality.

About Normansport

Normansport is a professional basketball manufacturer with advanced production equipment, a dedicated design team, and extensive export experience.

We provide one-stop OEM basketball manufacturing solutions for global customers—from product design, logo customization, and sample development to mass production and packaging for shipment.

Thanks to our exquisite craftsmanship and stringent quality standards, Normansport’s basketball products are highly sought after by buyers worldwide. If you’re looking for a reliable OEM basketball manufacturer, please contact Normansport and let’s work together to create your own basketball brand.