In today’s competitive sports market, a basketball is more than just equipment—it’s a brand carrier.

For basketball brands, clubs, schools, and distributors, custom logo basketballs play a crucial role in branding, team identity, and market differentiation.

However, many buyers still ask the same questions before placing an order:

-

Which custom logo basketball printing method is best?

-

How does printing affect cost?

-

How can I balance durability, appearance, and budget?

This guide breaks down custom basketball logo printing methods and the key cost factors every B2B buyer should understand before working with a manufacturer.

1. Why Logo Printing Matters in Basketball Manufacturing

For wholesale and OEM buyers, logo customization is not just decoration—it directly impacts:

-

Brand recognition in retail and tournaments

-

Perceived product quality

-

Durability and customer satisfaction

-

Production cost and MOQ strategy

Choosing the wrong printing method can lead to:

-

Fading logos

-

Peeling surfaces

-

Inconsistent branding across batches

That’s why understanding printing options at the manufacturing stage is essential.

2. Common Custom Logo Printing Methods for Basketballs

Different basketball materials require different printing technologies. Below are the most widely used methods in professional basketball manufacturing.

2.1 Silk Screen Printing (Screen Printing)

Best for:

-

Rubber basketballs

-

PU composite basketballs

-

Large-volume wholesale orders

Advantages:

-

Cost-effective for bulk production

-

Clear and sharp logo edges

-

Suitable for 1–3 color logos

Limitations:

-

Not ideal for complex gradients

-

Limited color layers

B2B Tip:

Silk screen printing is often the most economical option for promotional basketballs, school programs, and entry-level retail products.

2.2 Heat Transfer Printing

Best for:

-

PU and microfiber composite basketballs

-

Multi-color or gradient logos

Advantages:

-

Supports detailed designs and full-color graphics

-

Flexible for small-to-medium order quantities

Limitations:

-

Slightly higher unit cost

-

Logo durability depends on usage conditions

B2B Tip:

Heat transfer is popular for event basketballs, limited editions, and brand campaigns where visual impact matters more than extreme durability.

2.3 Embossed / Debossed Logos

Best for:

-

PU leather basketballs

-

Microfiber composite basketballs

Advantages:

-

Premium look and tactile feel

-

Logo does not fade or peel

-

Enhances brand positioning

Limitations:

-

Requires mold customization

-

Higher tooling cost

B2B Tip:

Embossed logos are ideal for mid-to-high-end basketball brands seeking long-term market presence and consistent branding.

2.4 Molded-In Logo (Integrated Logo)

Best for:

-

Rubber basketballs

-

Mass-market products

Advantages:

-

Extremely durable

-

No additional printing process required

-

Excellent for outdoor use

Limitations:

-

Limited design flexibility

-

Mold cost applies

B2B Tip:

This method works best for long-term wholesale programs where the same logo is used repeatedly.

3. Key Cost Factors in Custom Logo Basketball Production

Understanding what drives cost helps buyers make smarter sourcing decisions.

3.1 Printing Method Selection

Different methods directly affect:

-

Setup cost

-

Unit price

-

Minimum order quantity (MOQ)

| Printing Method | Relative Cost | MOQ Impact |

|---|---|---|

| Silk Screen | Low | Low |

| Heat Transfer | Medium | Medium |

| Embossed Logo | Medium–High | Higher |

| Molded-In Logo | High (tooling) | Best for large volume |

3.2 Number of Colors in the Logo

-

Single-color logos are the most cost-efficient

-

Multi-color or gradient designs increase labor and setup time

-

Each additional color may raise the unit price

Cost-saving strategy:

Simplifying logo colors can significantly reduce production costs without sacrificing brand recognition.

3.3 Basketball Material

Logo printing cost is also influenced by material choice:

-

Rubber: Lower printing cost, ideal for outdoor and promotional use

-

PU Composite: Balanced cost and branding quality

-

Microfiber Composite: Premium appearance, higher branding value

3.4 Order Quantity (MOQ)

Higher order volumes usually mean:

-

Lower unit cost

-

Better printing consistency

-

More flexibility in customization

For B2B buyers, aligning logo customization with annual sales planning helps maximize cost efficiency.

4. How to Choose the Right Printing Method for Your Market

Before placing an OEM or ODM order, consider:

-

Target market (school, retail, tournament, promotion)

-

Usage scenario (indoor, outdoor, training, competition)

-

Brand positioning (entry-level vs premium)

-

Budget and order volume

A professional basketball manufacturer should help you match logo technology with your business goals, not just quote a price.

5. Why Work with an Experienced Custom Basketball Manufacturer

An experienced manufacturer doesn’t just print logos—they help you avoid risks such as:

-

Inconsistent logo placement

-

Poor adhesion

-

Color deviation between batches

-

Unnecessary cost increases

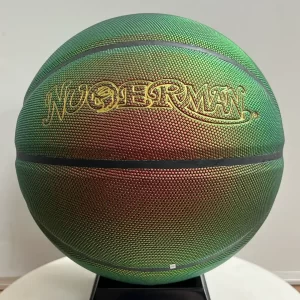

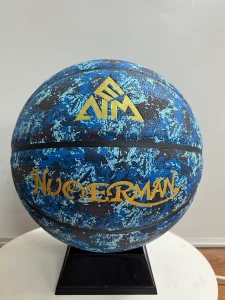

At Normansport, we specialize in OEM and ODM custom basketball manufacturing, offering:

-

Multiple logo printing solutions

-

Material-based printing recommendations

-

Stable quality control standards

-

Flexible MOQ for wholesale buyers

-

Support from sampling to mass production

Whether you are building a new basketball brand or expanding your product line, the right logo printing strategy can make a measurable difference.

Final Thoughts

Custom logo basketballs are a powerful branding tool—but only when the printing method, material, and cost structure are aligned with your market strategy.

By understanding the available printing technologies and their cost implications, B2B buyers can make smarter sourcing decisions and create basketball products that truly stand out.

If you’re planning your next custom basketball project, working with the right manufacturing partner is the first step toward long-term success.