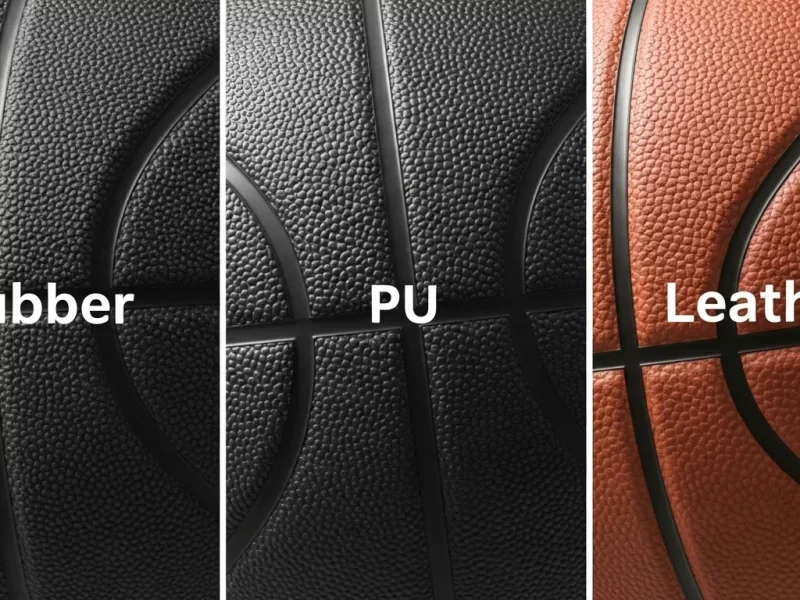

Choosing the right basketball material is one of the most critical decisions for brands, wholesalers, schools, and sports distributors.

Material choice directly affects performance, durability, cost, customization feasibility, and target market positioning.

In this guide, we break down the three most common basketball materials—Rubber, PU (Composite Leather), and Genuine Leather—from a B2B manufacturing and sourcing perspective, helping you select the most suitable option for your market.

Why Basketball Material Matters in Wholesale & Custom Manufacturing

For B2B buyers, basketball material is not just a technical detail—it impacts:

-

Unit cost & profit margin

-

Indoor vs. outdoor suitability

-

Logo printing durability

-

MOQ and customization flexibility

-

Customer satisfaction and repeat orders

Understanding material differences helps avoid mispositioned products, unnecessary returns, and price competition traps.

Rubber Basketballs: Cost-Effective & Outdoor-Focused

Key Characteristics

Rubber basketballs are made from molded or vulcanized rubber, designed for toughness rather than premium feel.

Advantages for B2B Buyers

-

Excellent abrasion resistance for outdoor courts

-

Lower production cost

-

Ideal for bulk orders, schools, and promotions

-

Stable performance in rough environments

Limitations

-

Harder touch and limited grip

-

Less suitable for professional indoor play

-

Basic appearance compared to PU or leather

Best Use Scenarios

-

Schools & youth training programs

-

Outdoor courts & street basketball

-

Promotional and entry-level retail products

From a wholesale perspective, rubber basketballs are ideal when price sensitivity and durability outweigh premium branding needs.

PU Basketballs (Composite Leather): The Most Versatile Choice

What Is PU Basketball Material?

PU (Polyurethane) composite leather basketballs use layered synthetic materials designed to simulate the feel of leather while improving durability and consistency.

Advantages for OEM & ODM Projects

-

Soft touch and strong grip control

-

Suitable for both indoor and limited outdoor use

-

Excellent surface for logo printing and custom designs

-

Stable quality across large production batches

-

Competitive balance between cost and performance

Customization Benefits

PU basketballs support:

-

Multi-color printing

-

Deep embossing or debossing logos

-

Matte, glossy, or microfiber textures

-

Consistent branding for teams and tournaments

Best Use Scenarios

-

Club and league competitions

-

Mid-to-high-end retail brands

-

Custom logo basketballs for events

-

Training balls for schools and academies

For most B2B buyers, PU basketballs are the most commercially flexible and scalable option.

Genuine Leather Basketballs: Premium & Professional Standard

Material Overview

Genuine leather basketballs are typically made from cowhide and are used in professional-level indoor games.

Advantages

-

Superior grip after break-in

-

Premium look and feel

-

Strong association with professional leagues

Limitations for Wholesale Buyers

-

Higher material and production costs

-

Requires break-in period

-

Not suitable for outdoor use

-

Limited flexibility for large-scale customization

Best Use Scenarios

-

Professional indoor competitions

-

High-end collector or flagship products

-

Limited-quantity premium branding

Leather basketballs are not ideal for mass OEM orders, but they work well for high-end positioning and brand prestige.

PU vs. Rubber vs. Leather: A Quick Comparison

| Feature | Rubber | PU (Composite) | Genuine Leather |

|---|---|---|---|

| Cost Level | Low | Medium | High |

| Grip Feel | Hard | Soft & Controlled | Excellent (after break-in) |

| Indoor Use | Limited | Excellent | Excellent |

| Outdoor Use | Excellent | Moderate | Not suitable |

| Custom Logo Printing | Basic | Excellent | Limited |

| OEM Scalability | High | Very High | Low |

How B2B Buyers Should Choose the Right Material

When sourcing basketballs in bulk or planning custom production, consider:

-

Target Market

-

Schools & youth → Rubber or PU

-

Clubs & leagues → PU

-

Professional indoor → Leather

-

-

Usage Environment

-

Outdoor-heavy use → Rubber

-

Mixed indoor/outdoor → PU

-

Indoor-only competition → Leather

-

-

Brand Positioning

-

Promotional & entry-level → Rubber

-

Branded retail & teams → PU

-

Premium image → Leather

-

-

Customization Needs

-

Complex logos & color designs → PU

-

Simple branding → Rubber

-

Minimal customization → Leather

-

Why Many Brands Choose PU Basketballs for OEM Manufacturing

From a manufacturer’s perspective, PU basketballs offer the best balance between quality control, cost efficiency, and customization scalability.

They allow brands to:

-

Maintain consistent product quality

-

Support flexible MOQ requirements

-

Create strong visual brand identity

-

Adapt products for different markets

This is why PU composite leather basketballs dominate modern wholesale and custom basketball manufacturing.

Final Thoughts: Match Material with Market Strategy

There is no “best” basketball material—only the right material for your specific market and business goals.

-

Rubber basketballs win on cost and durability

-

PU basketballs dominate in customization and versatility

-

Leather basketballs represent premium professionalism

Understanding these differences helps B2B buyers build competitive product lines, reduce sourcing risk, and strengthen long-term brand value.