With the global popularity of basketball, it has long since transcended being just a standardized sporting item. For sports brands, schools, clubs, event organizers, and wholesalers, customized basketballs have become a crucial way to differentiate their brands and enhance their market competitiveness.

In today’s basketball manufacturing industry, customization extends beyond appearance to include size, materials, craftsmanship, and packaging. So, in actual custom basketball projects, which customization options are the most common and popular in the market?

This article will systematically introduce the 5 core customization options in basketball manufacturing, helping you make more professional decisions when sourcing or developing basketball products.

1. Basketball Size Customization

Size is one of the most basic and important customization options in basketball manufacturing. Different user groups and application scenarios have specific requirements for basketball size.

Common basketball sizes include:

- Size 7: Standard adult men’s game ball

- Size 6: Women’s game ball and youth ball

- Size 5: Children’s training and school basketball

- Smaller sizes: Promotional, commemorative, or promotional purposes

For B2B buyers, choosing the right size not only affects the user experience but also directly relates to target market positioning. During the basketball manufacturing process, professional manufacturers strictly control the ball’s diameter, weight, and airtightness according to customer needs, ensuring that each custom basketball meets international or customer-specified standards.

2. Basketball Material Customization

The material determines a basketball’s feel, durability, and applicable environment, making it one of the most critical factors in custom basketball.

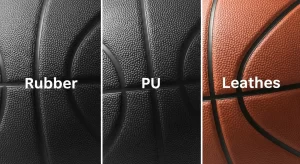

Common basketball material choices:

- Rubber basketball: Highly durable, suitable for outdoor courts and the entry-level market.

- PU basketball: Soft feel, high cost-performance ratio, widely used in training and commercial applications.

- Synthetic leather/genuine leather basketball: Feels close to game-level, suitable for the high-end market and professional events.

Different materials differ significantly in cost, lifespan, and market positioning. Experienced basketball manufacturers typically offer reasonable material matching suggestions based on the client’s sales channels (retail/wholesale/project procurement) and budget.

3. Logo Customization

Logo customization is the most valuable part of basketball customization and a core requirement that most B2B clients prioritize.

Common logo customization methods include:

- Screen printing

- Hot stamping/embossing

- Multi-color printing or special effects printing

Whether it’s a brand logo, school name, club logo, or event commemorative design, logo customization significantly enhances the basketball’s recognizability and brand exposure.

During basketball manufacturing, the clarity, durability, and consistency of the logo place high demands on the manufacturing process. Professional custom basketball suppliers repeatedly confirm the effect during the sampling stage to ensure the stability of mass production.

4. Color & Design Customization

Besides the logo, color and overall design are also crucial factors influencing market appeal.

Common color and design customization options include:

- Classic orange basketball

- Black, white, or branded custom colors

- Panel color combinations

- Line colors and texture designs

Through color customization, brands can make basketball products better fit their visual identity, enhancing market recognition. For promotional projects or event-customized basketballs, unique designs often bring higher added value.

In custom basketball projects, the combination of design and manufacturing capabilities determines whether the final product is truly “good-looking and functional.”

5. Packaging Customization

In B2B procurement, packaging is often overlooked, but it actually has a direct impact on sales and brand image.

Common basketball packaging formats include:

- Single ball simple packaging

- Color box retail packaging

- Custom gift boxes or promotional packaging

Custom packaging not only helps protect the product but also enhances its overall quality, especially suitable for retail, e-commerce, or brand promotion scenarios. In professional basketball manufacturing services, packaging is usually part of a one-stop customization solution, helping clients save on communication and procurement costs.

Why choose a professional basketball manufacturer for customization?

Basketball customization is not simply about “slapping on a logo,” but a systematic engineering process involving design, materials, craftsmanship, and quality control. Choosing an experienced manufacturer offers the following advantages:

- Consistent and stable product quality

- Mature customization processes and prototyping support

- More efficient mass production capabilities and guaranteed delivery times

- More market-oriented professional advice

For brands and wholesale clients looking for long-term growth, a reliable basketball manufacturing partner is especially important.

About Normansport

Normansport is a professional basketball manufacturer that continuously develops a variety of high-quality basketball products, leveraging a professional design team, skilled manufacturing processes, and extensive production experience.

Our basketballs are loved by buyers worldwide and are widely used in training, games, schools, clubs, and commercial promotions. Normansport is also a trusted custom basketball supplier, supporting customization needs for basketball size, materials, logos, colors, and packaging.

If you are looking for a stable, professional, and experienced basketball manufacturing partner, Normansport is your ideal choice.